Cutting Tools

Composite Cutter Technology offers custom and standard size Polycrystalline Diamond (PCD), Cubic Boron Nitride (CBN), carbide and high-speed steel (HSS) precision cutting tools to help improve your manufacturing processes. Choose us for high-quality cutting tools such as inserts, end mills, boring bars, root tools, drills, reamers, countersinks, and many others.

Our engineers are eager to work with you to develop the most efficient PCD tool for your specific application. PCD and CBN cutting tools provide many benefits including the excellent quality finish on the completed part, decreased tool changes, decreased scrap, and increased machine utilization for long runs and hard-to-machine materials. HSS is a more economical solution for short production runs or when tool longevity is not a concern.

When buying cutting tools, you have the option to purchase new tools, retipped tools, and resharpened tools. Re-tipping and resharpening tools are economical solutions to help lower costs.

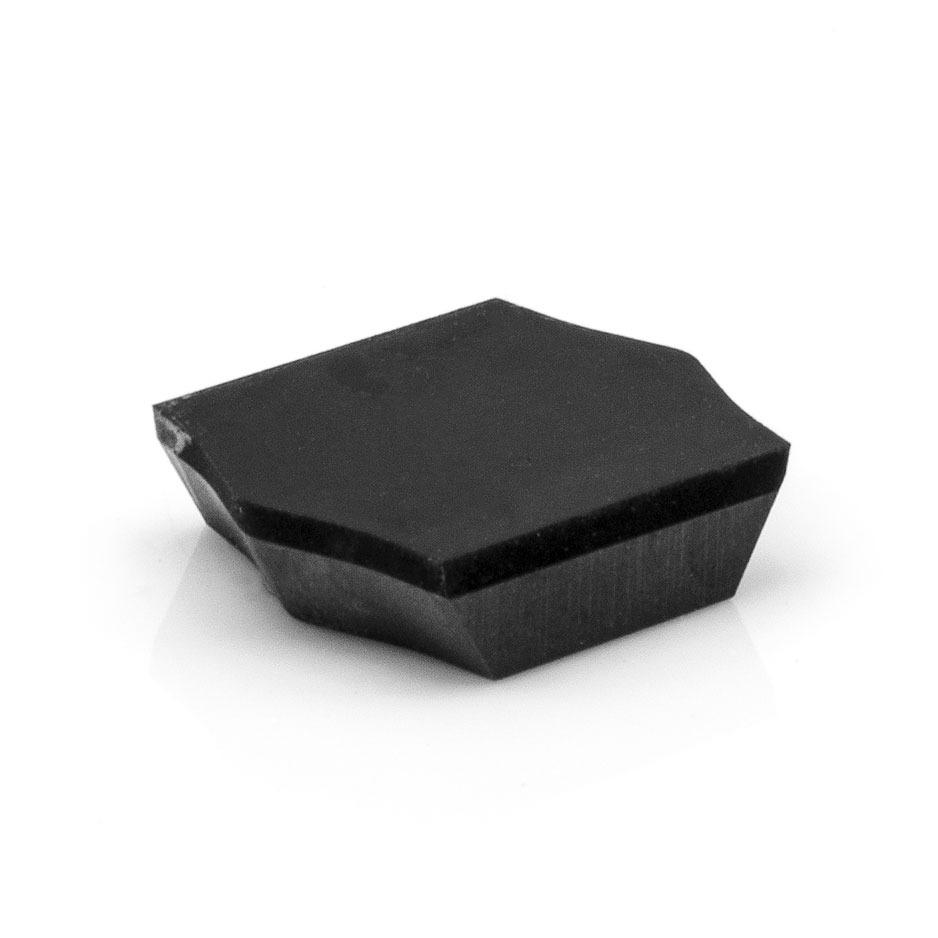

Polycrystalline Diamond, PCD, is the hardest known material and has many advantages in manufacturing. PCD is a synthetic diamond produced by sintering together micron-sized pieces of diamond powder with a metal binder, typically cobalt, under extreme pressure and temperatures. The cobalt adds toughness to the material and renders the material electrical conductive. The carbide substrate provides a brazeable layer of material.

PCD is extremely abrasion resistant and PCD tools can have a 50-100 times longer tool life compared to conventional tools. PCD is recommended for machining non-ferrous and non-metallic materials such as aluminium, brass, composite materials, copper, fiberglass, green ceramics and carbides.

Polycrystalline Cubic Boron Nitride, CBN, is the seconded hardest known material after PCD and has many advantages in manufacturing. CBN is produced by sintering together micron-sized pieces of cubic boron nitride with ceramic materials under extreme pressure and temperatures. The carbide substrate provides a brazeable layer of material.

CBN is extremely abrasion resistant and has a high thermal stability. CBN is recommended for machining ferrous materials such hardened steels, cast iron, powdered metals and super alloys.

High-speed steel (HSS) is a high-carbon and high-alloy steel which has been around for centuries. HSS is heat-treated to strengthen the material and increases its hardness and abrasion resistance. Tool coating processes, such as Chemical and Physical Vapor Deposition (CVD and PVD), provide a coating to improve tool performance, the ability to run at high speeds with sharp cutting edges and extend tool life.

HSS has good toughness, impact resistance and low hardness. One of the biggest advantages of high-speed steel tools is that they can easily be resharpened.

Carbide is a compound of carbon and metal. Cemented carbides are powders and binders fired at high temperatures. Tungsten carbide is a runner up to diamond for the hardest known material, has high toughness and good wear resistance. Carbide shapes are typically pressed using a die or machined to the shape required.