Currently, there are numerous kinds of materials for cutting tools on the market. There is no “perfect” material meeting all the needs for all the applications. Let’s compare polycrystalline diamond (PCD) and carbide cutting tools.

PCD is a synthetic diamond manufactured by sintering together micron-sized pieces of diamond particles with a metal binder, typically cobalt, under intense pressure and temperatures. Polycrystalline diamond is the hardest man-made material on the planet and demonstrates extreme hardness, high abrasion resistance, and an excellent option for cutting tools. The hard PCD cutting edge provides high resistance to wear, longer machining runs, and improved surface finish on the manufactured product. PCD cutting tools can have up to a 50-100 longer tool life than other materials. Diamond tool handling requires special care and handling techniques to prevent any damage while the tool is not in use. PCD is the material choice for machining abrasive materials and is recommended for machining non-ferrous materials such as aluminum, brass, composite materials, copper, fiberglass, green ceramics, etc.

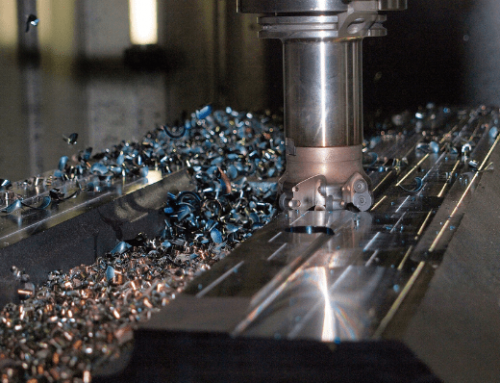

Carbide is a compound material made by pressing and sintering tungsten carbide particles with cobalt and nickel. Carbide is a hard material and with high compressive toughness. Carbide is used for indexable cutting tool inserts and full carbide cutting tools depending on the strength of the tool required. While they outlast conventional steel tools and they have a shorter life than PCD. Carbide tools provide an economical solution for short manufacturing runs where PCD is too expensive. Carbide is used for machining stainless steel, cast iron titanium alloy, and non-ferrous materials.

You can rely on our engineers when looking for the best tool to fit your specific needs. Some specific information we need to get started include the following:

- The material you want to process with our tools.

- How long you plan to use the tools: days, weeks, or months.

- Surface finish quality requirements.

By providing such information, you are helping us create the proper tool, including the grade of PCD (from submicron to multi-modal grain size) or carbide to fit various applications.

Whether you need PCD, CBN, carbide, HSS, or different types of cutting tools, our engineers are here to help you make the best decision for your application. Feel free to request a quote or call us at (847) 740‑6875.