At some point, that question arises inevitably: is it possible to replace a worn tool, or can it be repaired? Each option has its advantages. By purchasing a new cutting tool, you receive a kind of warranty that it will have a perfect finish and longer tool life. However, if you think about a more economical solution, reconditioning tool service is a solid choice if done by experts like us.

Composite Cutter Technology is pleased to offer a variety of services: from manufacturing new custom tools to re-tipping and re-sharpening the used PCD tools. You can trust us on that: we have been in this business since 1983. Our engineers will evaluate a tool’s condition (coating, tool wear type, and location of the damage(s)) and recommend the best option for each particular case. Generally speaking, each kind of wear has a cause and a cost-effective solution.

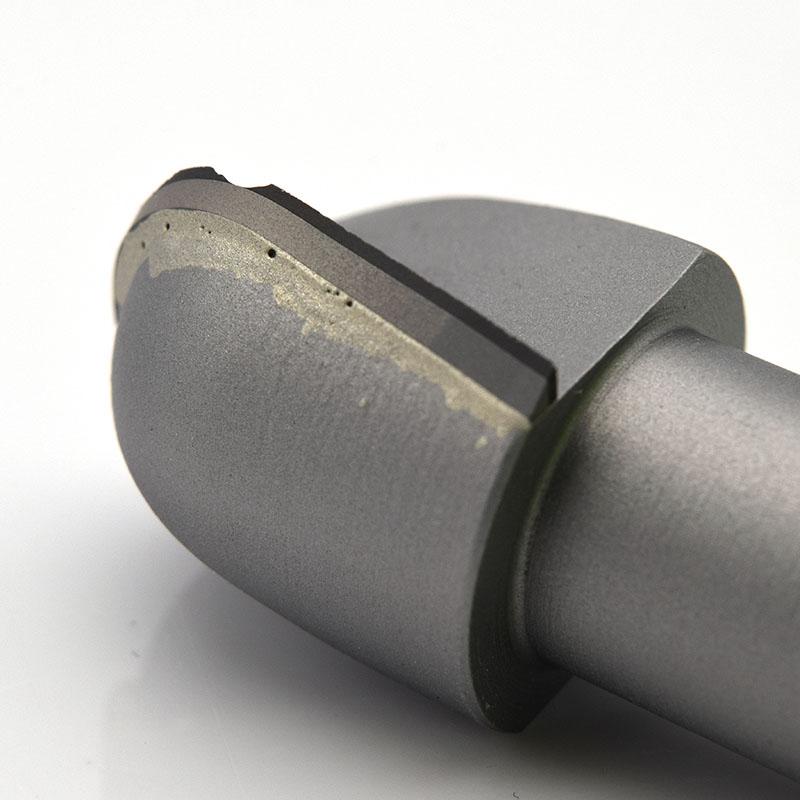

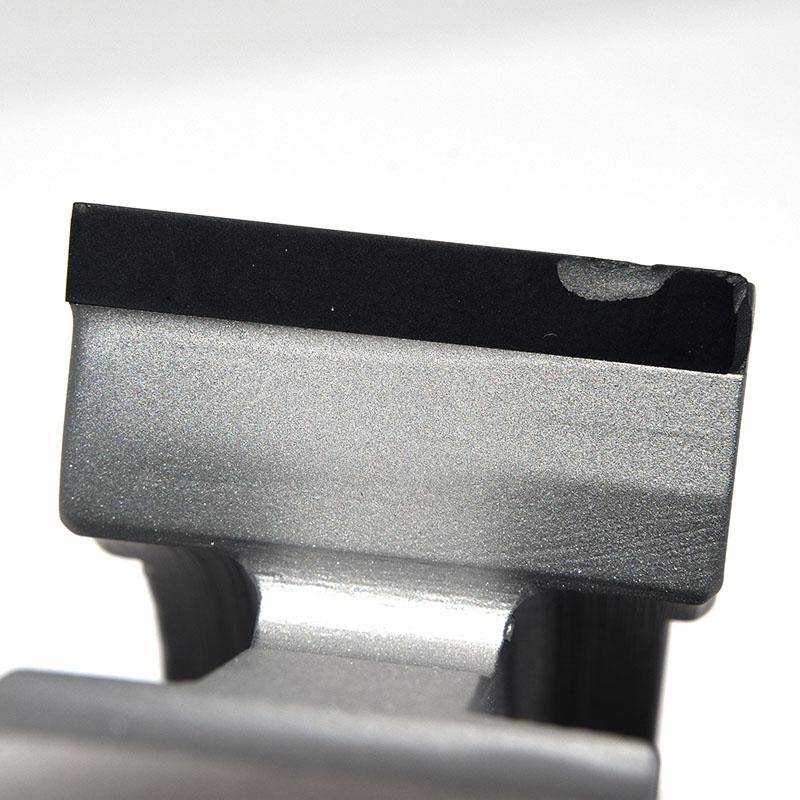

Some examples of the tool wear or damage that can be repaired:

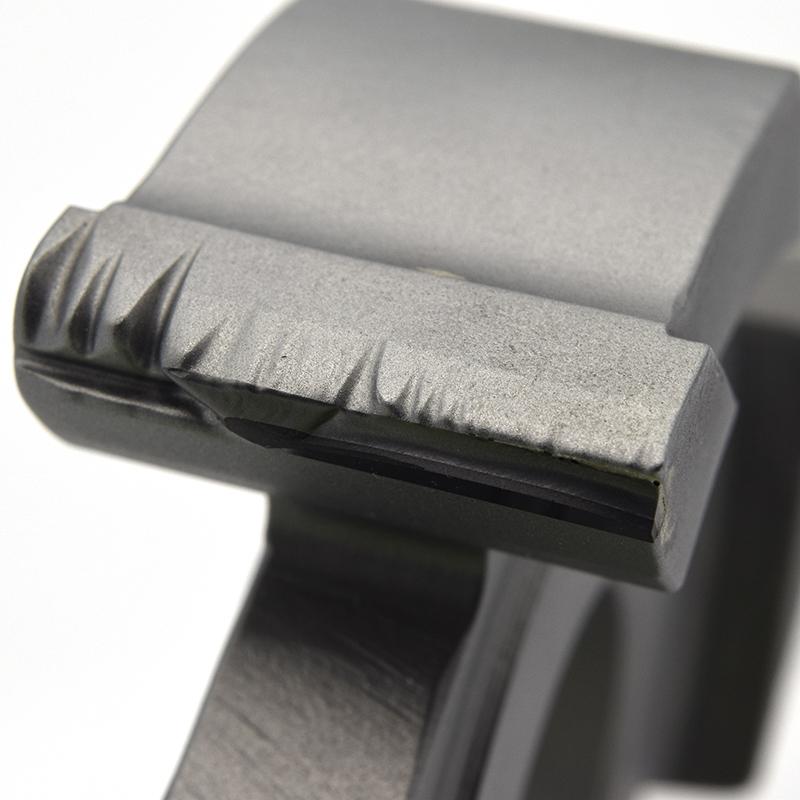

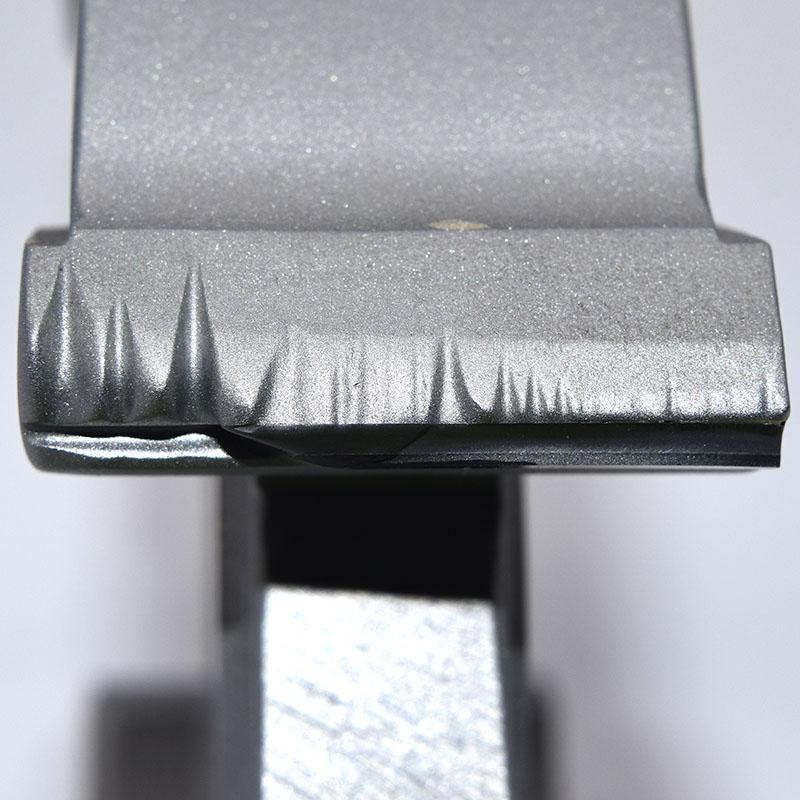

Not every damage can be fixed; for example, this PCD tool below crashed in the machine and cannot be repaired. That is why well-timed tool maintenance is critical.

You can always rely on our quality standard to repair or rebuild all of the PCD tools we produce (these are CBN and PCD tools, respectively): drills, end mills, reamers, inserts, countersinks, and other types.

At Composite Cutter Technology, we recognize the importance of your investments. Please think twice before giving up on the old tools: you could use them longer than you assume without compromising the quality. Contact us today to discuss the best strategy for your continuous production cycle.