Precision machining, an advanced manufacturing technique, is the removal of material resulting in a close tolerance part. Composite Cutter Technology partners with local manufactures to be the one-stop shop for all your machining needs. We have advanced machine tools, software and highly-experienced operators. Our multi-axis work cells supply the machining necessary to provide accurate parts for our customers.

Types of CNC Machines

EDM

EDM is the removal process where a thin wire is used to cut through conductive materials such as polycrystalline diamond, polycrystalline cubic boron nitride, aluminum, steel and carbide. The stationary workpiece is submerged in deionized water and the wire is used to change the shape and size of the workpiece. CNC Wire EDM machines are used at CCT with wire diameter as small as 0.002”.

Current equipment list contains 7 EDM machines, including CNC:

- FANUC RoboCut C400iB-10

- Sodick AQ327L (5 axis)

- Accutex SP-500 (5 axis)

- 3x Charmilles Andrew EF 320/330 (4 axis)

- Agie 100 C (5 axis)

Turning

Turning is a machining process where the work piece rotates and the cutting tool remains stationary. Turning is commonly used to describe removing material on the external surfaces and boring is commonly used to describe removing internal surface material. The work piece can be reshaped and resized. Both turning and boring are completed on a CNC, computer numerical control, lathe.

Current equipment list includes 9 CNC turning centers, 5 axis, sub spindles, twin turret, bar capacity .25″ – 2.75″, horsepower up to 30 hp:

- 7x Daewoo / Doosan

- Milltronics

- Turnmaster

- Clausing (manual)

- Hardinge (manual)

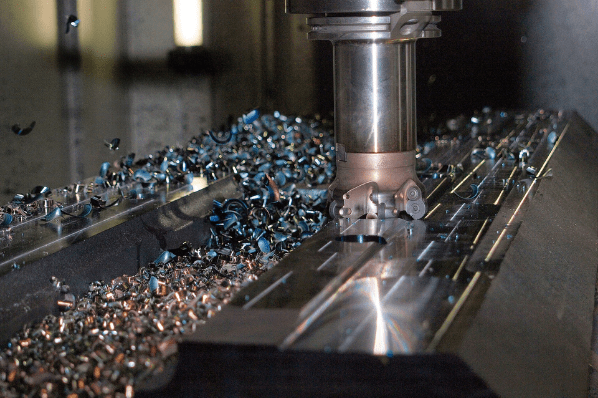

Milling

Milling is a machining process where the work piece is stationary and the cutting tool rotates and advances to remove material. Endmills, router and inserts are used to shape the material to the close tolerances noted on the prints. The work piece can be resized and reshaped using a CNC mill.

Current equipment list includes 21 vertical machining centers, 4 axis, machine travels 20″ x 40″, horsepower 3.5 — 25 hp:

- 11x Milltronics VMC (conversational controls)

- 4x Daewoo VMC

- Leadwell (pallet machine)

- Hurco VMC

- Okuma VMC

- SWI Trak VMC

Grinding

Grinding is the act of removing material by using abrasive wheels to remove the material on the work piece. The grinding wheel rotates and acts as a cutting tool while the work piece either rotates or remains stationary depending on the tool requirements. Grinding leaves a high quality surface finish and close tolerances. CCT utilizes with both CNC and manual grinding machines.

Current equipment list contains 9 grinding machines including CNC, hydraulic and manual operation:

- Chevalier Smart CNC- H1224II

- 4x Grind‑X Okamoto ACC12-24DXB

- Boyar Shultz (Hyd)

- Mitsui (manual)

- 2x Makino C‑40 Universal Cutter Grinder

- Additional supportive equipment

- Brazing equipment, in-house heat treating, in-house anodizing, inspection equipment and support equipment for all the precision machining services

Let us know if you have any questions about precision machining.